An architect contacted us the other day with an interesting question. She asked whether it's possible to control the finish on our natural steel diamond shingles, or whether the patina will simply develop on its own over time.

An architect contacted us the other day with an interesting question. She asked whether it's possible to control the finish on our natural steel diamond shingles, or whether the patina will simply develop on its own over time.

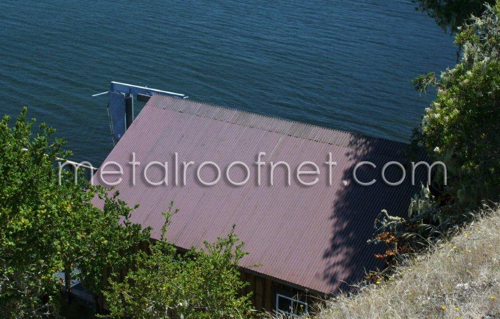

It's a great question, and there are long and short answers. With most natural metals (steel, aluminum, copper, zinc, etc.), exposure to weather begins the process of corrosion that is referred to as “patina.” In some metals it continues rather quickly, and in others it’s a very slow process. The slower the process, the more “corrosion resistant” the metal. In the case of copper, the patina that forms is famous for helping protect the base metal and making copper very corrosion resistant and quite beautiful in the process.

Natural carbon steel doesn’t have the corrosion resistance of a metal like copper and so the patina that forms isn’t as protective of the base metal (as in the case of copper), which is why the corrosion process tends to be more rapid. While it corrodes (“rust” is the term applied to steel) it can be quite lovely in the eyes of many. If one were to install a steel roof, allow it to react with the air and rain for a while, and then decide that they wanted to arrest further corrosion ("Let's stop it right there!"), it is possible to apply a clear sealer over top of the rusted roof to prevent further corrosion. The clear sealer could be rolled on or sprayed, and even though painting a sealer onto a sloped roof poses its own set of logistical issues, you wouldn’t be the first to take on such a project.

Natural carbon steel doesn’t have the corrosion resistance of a metal like copper and so the patina that forms isn’t as protective of the base metal (as in the case of copper), which is why the corrosion process tends to be more rapid. While it corrodes (“rust” is the term applied to steel) it can be quite lovely in the eyes of many. If one were to install a steel roof, allow it to react with the air and rain for a while, and then decide that they wanted to arrest further corrosion ("Let's stop it right there!"), it is possible to apply a clear sealer over top of the rusted roof to prevent further corrosion. The clear sealer could be rolled on or sprayed, and even though painting a sealer onto a sloped roof poses its own set of logistical issues, you wouldn’t be the first to take on such a project.

So the short answer is, yes, you can control the finish of natural metal roofs. The feasibility and cost of such a task, however, will depend on the roof itself. If you're considering such a project, I’d be very interested in learning about what you have on the drawing board! Contact us and we'll be happy to help.